At Phoenix Precision Machining, our machine shop includes twelve automated CNC turning centers, 1 Robot, and ten CNC machine centers, enabling us to provide single-source manufacturing services to customers across a variety of industries. We can work with an expansive range of materials, such as aluminum, die castings, non-ferrous metals, plastics, and steel. We administer comprehensive quality assurance testing and visually inspect all parts before they leave our shop to ensure they meet our standards for superior functionality and aesthetic value.

We specialize in working on challenging projects for customers in demanding industries — here are some of the industries we most frequently work with.

Robotics/Automation

The first customer we ever served was in the robotics and automation sector and we continue partnerships with this industry today. These applications require extremely precise parts, as inaccurate components simply won’t work at all or might cause equipment damage if they do.

The first customer we ever served was in the robotics and automation sector and we continue partnerships with this industry today. These applications require extremely precise parts, as inaccurate components simply won’t work at all or might cause equipment damage if they do.

We work within incredibly close tolerances, which makes us an ideal provider of components used in automation and robotics technologies. We have also worked with customers to realize completely new designs, and to produce unique components used in maintenance and repair operations.

Some of the products we’ve produced for this industry include:

- Fanuc robotics

- Metrology equipment

- Tool changers

Aerospace

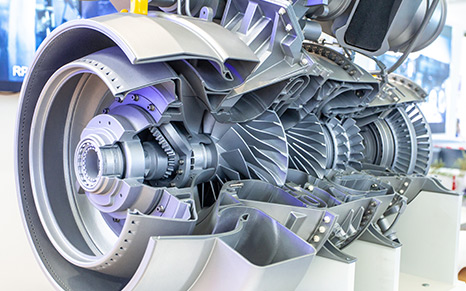

At Phoenix Precision Machining, we’ve worked with a variety of major aircraft OEMs to produce highly precise aerospace parts. Aerospace customers come to us not only for our close-tolerance precision machining capabilities, but our quality certifications and traceability competence.

At Phoenix Precision Machining, we’ve worked with a variety of major aircraft OEMs to produce highly precise aerospace parts. Aerospace customers come to us not only for our close-tolerance precision machining capabilities, but our quality certifications and traceability competence.

We can provide paperwork in accordance with stringent standards such as AS9102, revision B; FAIR; COC, and much more. We source all of our materials in the United States and keep paperwork on file for 30 years to satisfy even the strictest traceability requirements.

Here are some examples components we have produced on behalf of aerospace OEMs:

- Canisters

- Filter bowls

- Filtration components

- Hydraulic fittings

Medical

We’re proud to provide manufacturing support for critical medical equipment. We implement rigorous cleanliness and purity practices into our production line for medical projects. Our team conducts hand deburring on each piece to ensure we only release medical components with surface finishes of 20 RA or better.

We’re proud to provide manufacturing support for critical medical equipment. We implement rigorous cleanliness and purity practices into our production line for medical projects. Our team conducts hand deburring on each piece to ensure we only release medical components with surface finishes of 20 RA or better.

We use only materials sourced in the United States, and we can mark and engrave parts for increased traceability. Most recently, we have been supporting medical OEMs in building pressure ventilators.

Military/Defense

We’re proud to serve the U.S. Military and Department of Defense with our precision manufacturing capabilities. We produce only the highest-quality parts, ensuring proper functionality even in harsh conditions and mission-critical applications. We offer full traceability and regulatory documentation for all projects and materials.

We’re proud to serve the U.S. Military and Department of Defense with our precision manufacturing capabilities. We produce only the highest-quality parts, ensuring proper functionality even in harsh conditions and mission-critical applications. We offer full traceability and regulatory documentation for all projects and materials.

Our materials are sourced in the United States, enabling us to support increased legislation and efforts to source military goods and components domestically. We can adhere to non-disclosure agreements and any other requirements as needed.

We have experience with military and defense parts such as:

- Helicopter components

- Firearm parts

- Vehicle components